Basic information

Advantages of the model

1、The die head adopts four layer coextrusion technology, which can extrude the plastic products with four layers of wall thickness.

2、Good precision linear guide rail mold closing action, 125 mold locking cylinder, large mold locking force.

3、The swing frame is controlled by servo valve, with fast start, stable and accurate brake positioning, stable and accurate mold moving, and adjustable mold moving stroke.

4、High precision linear guide inserting pen, faster response speed, and smooth movement.

5、A number of utility model patents are applied to the product.

Characteristics of machine performance

1、The linear guide rail of the pen holder has the advantages of small friction force, high guiding accuracy, and overall adjustment of the left and right before and after the pen holder.

2、The pen holder can be adjusted up and down to transport water, without water pipe and air pipe.

3、The industrial control computer with high reliability and stability (with touch operation screen) is used to control the action and temperature (with PID function).

4、Equipped with lifting platform, equipped with water inlet material removal device.

5、It adopts pneumatic and electrical control elements of famous factory, with long service life.

6、It can be equipped with automatic feeding device and product conveying device, which is convenient for assembly line production.

7、The extruder motor adopts frequency control, which can meet the requirements of screw speed change in blow molding process.

8、The model is equipped with thickness control function, which is very accurate for the thickness control of bottle wall.

Model selection function

1. To facilitate the feeding, the user can choose to increase the hydraulic automatic filter screen device, which can be added to the lower blow, wall thickness controller, automatic incision drawing or automatic deplaning device;

2. Optional pre-sealing cutting knife, transverse cutting knife, imported hot knife, cold cutting knife, etc.

3. Optional diagonal insert, insert pen, insert pen, auxiliary cooler, etc.

4. Optional thickness controller;

5. Optional and equipped with the self-development of lego machinery for permanent magnet brushless dc motor for plastic hollow moulding machines: high reliability, good stability, and comprehensive energy saving 8% to 15%;

6. Optional macromolecular mixing screw: to ensure the performance of products, save 15% to 30% of the raw materials;

7. Optional Austria SIGMATEK control system, which performs 10 times faster than the traditional cycle refresh mode;

8. optional remote service system: automatic fault diagnosis, maintenance records, statistics report, video transmission, remote SMS notification and alarm, etc., used a powerful, clear;

9. Optional air delivery system, conveyor belt, automatic feeding system, 4 integration feeding machine and other supporting functions;

10. Optional die top needle function, mould internal labeling function, online leak detection function, opening and closing function;

11. Optional before and after mobile platform to facilitate mold installation;

12. Optional pre-clamping function, 2-axis servomotor, uniaxial servomotor;

13. The user can select the shunt spindle, screw or row type mould head, continuous extrusion die head and storage mould head.

14. Optional with a large pen blowing function to quickly increase production.

15. Optional robotic manipulator is used to combine the functions of secondary blowing and sizing and blowing and leak detection.

16. Optional boring machine (inside and outside the machine) can meet the requirements of different product sizes to make the product bottle mouth smoother.

Operation and precautions of aircraft

1. Preparation before production

1.1 check whether the machine has zero and component damage, check whether the screw is loose, check whether the wires and cables are damaged or lost. If there is any damage, replace or repair it in time; Check to see if there is debris in the extruder hopper and clean up, then close the material gate.

1.2 check whether the moving parts are firm and the screws are loose and loose, especially where the impact force is stronger, whether the belt transmission part is abnormal.

1.3 check the high pressure gas source, low pressure air source, power supply and water supply.

1.4 check the emergency stop switch, safety door switch and protection device to check whether the switch is normal.

1.5 check whether all pneumatic components leak gas, whether the action is sensitive.

1.6 please operate according to the operation manual.

2. Normal production

When the machine is normally produced, a person should be responsible for the care, and the issue will be timely handled. Due to the high degree of automation of the machine, the workload of normal production is very low, and the user can only need to collect the raw materials at regular intervals and use the container to collect the products and the flying side materials in the designated position of the machine.

Machine maintenance and maintenance

To enable the machine to achieve optimal performance and extend service life, the machine should be inspected and maintained regularly.

Please call:+86-757-29376175, +86-757-28376210,Consulting.

Product details

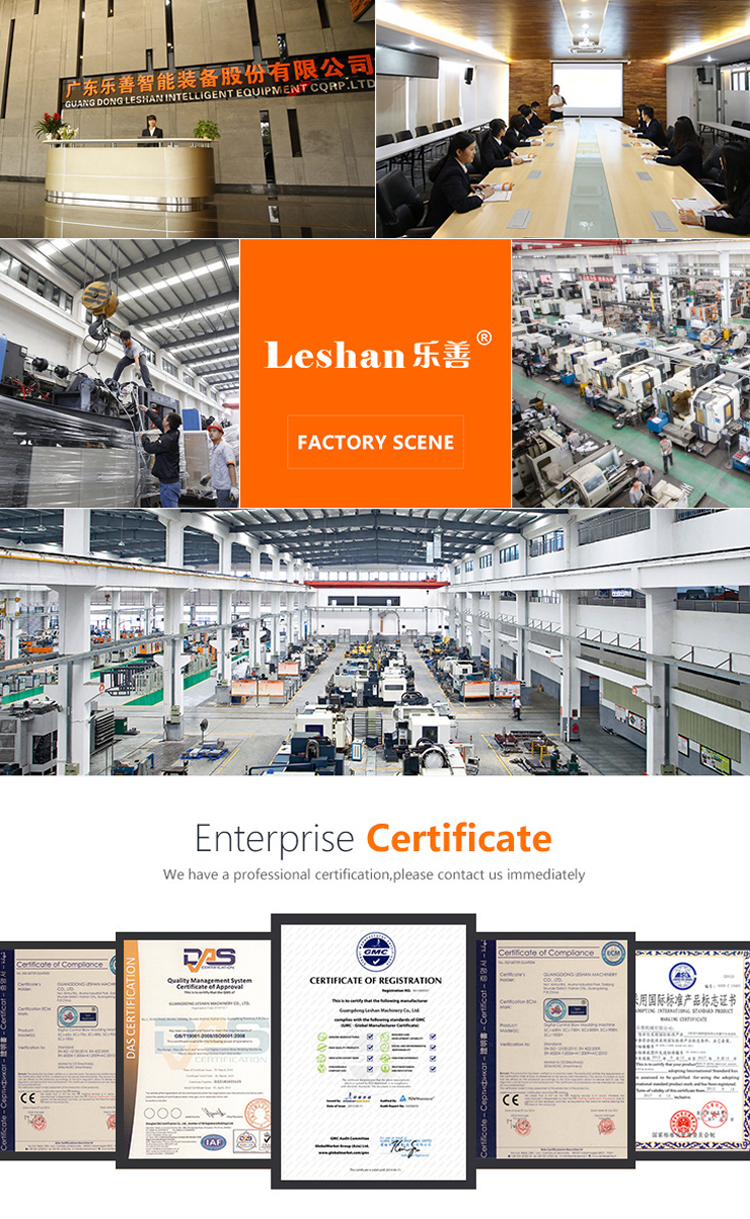

About Leshan

Not"blow" can do Leshan bottle blowing machine

Stock name:Leshan Intelligent

Stock code:871695

LESHAN is the new three board listed company (an over-the-counter market for growth enterprises). Founded in August 1995, Leshan is located in Wusha Industrial Park,Daliang,Shunde District,Foshan City. It covers 37570m2 and there are over 330 staffs. Now Leshan has developed into a intelligent equipment enterprise which concentrates on plastics extrusion, design,R&D,production, marketing and service of blow molding machine.

Language

Language

Please call

Please call Consultation

Consultation