Welcome to visit Leshan The official website!

Key engineering

From the stand-alone to the whole, from the entire line to the turnkey

project, Leshan has been to customers as the core, never interrupted

for customers to improve product quality and service levels.

project, Leshan has been to customers as the core, never interrupted

for customers to improve product quality and service levels.

Member

Leshan Machinery has been specializing in blowing technology for 26 years. Our "Key Engineering" teamhas over 20 years of experience in the blow molding machine industry, including 15 years in blow molding

machine design and over 5 years in industrial plant design , More than 10 years experience in assembly fitter

experience and workshop management experience of technicians, there are also electricians, welders, fitter

diversified talent, are familiar with blowing machine installation and commissioning technicians and so on.

Service

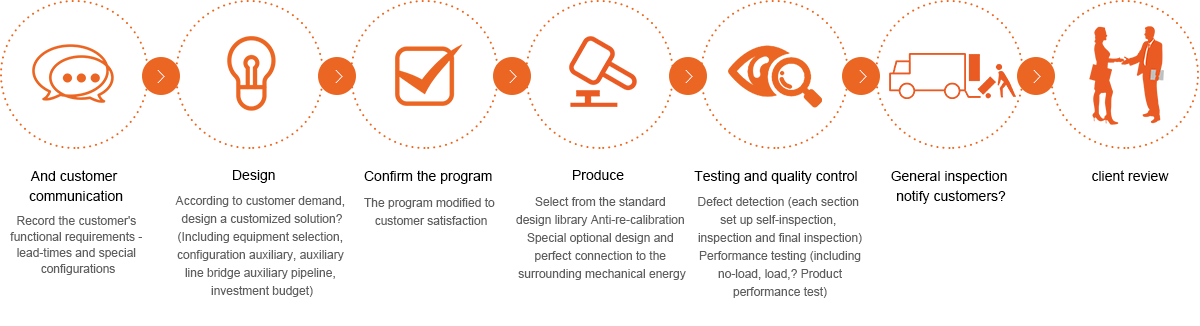

According to the production process and the principle of logistics and transport facilities, we plant (new or modified) function is divided into raw materials, ingredients, blowing workshop, injection workshop, filling workshop and warehouse. At the same time, we will design a set by the ratio of raw materials, raw material handling, waste crushed into the bottle blowing, the bottle in addition to benefits and the bottle standing overall solutionConstruction

From the selection of the part of the waterway part of the workshop, gas section, electrical part, pipeline bridge part to the procurement and inspection, from the hole, welding, polishing, installation, cleaning, commissioning to test the finished product, Independent contract.work process

We are professional, so you convince

Successfully provided key engineering services to the following clients

Concept customizatton

-

Listen

Leshan sales engineers carefully listen to customer requirements for product quality, functional requirements of the machine, factory layout and business planning, and other aspects of the views, to choose the most suitable for customers models

-

Interflow

Leshan Sales Engineer will communicate with P & D and Production Installation to get the best solution and submit it to the customer. -

Proposal

Leshan sales engineer to the customer site visits, the program modulation the best

-

Design

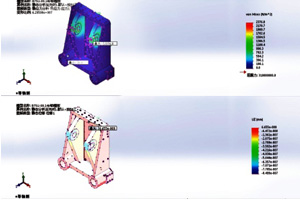

Leshan uses SolidWorks and 3D software for all designs, with "simulation tests" that simulate the mounting dimensions, loads, and digital design throughout the entire R & D process

-

3D CAD

Effectively improve the design efficiency and accuracy

-

Simulation test

Through repeated simulation calculation, analysis of the machine under the force of the changes in the state of the load on the life of the product which impact and optimize it

Language

Language