Welcome to visit Leshan The official website!

Athlon Series Machine (Part 2)

Announcer:Leshan Time:2020-05-29

In recent years, due to the continuous increase in operating costs such as labor wages, factory rents, and material prices, the bottle blowing industry has become more and more competitive with the industry, the accuracy requirements of bottles are getting higher, and the profit margin is getting thinner! In such a large environment, the bottle-blowing factory must maintain its competitiveness and put forward higher requirements on the performance of the bottle-blowing machine: the capacity of the single machine should be higher; the performance of the equipment should be more stable; and labor can be saved through automation.

Leshan has been established for more than 20 years and has witnessed the vigorous development of the bottle blowing industry. How does Leshan's new Athlon bottle blowing machine series lead the industry's technological innovation? Read on to learn more!

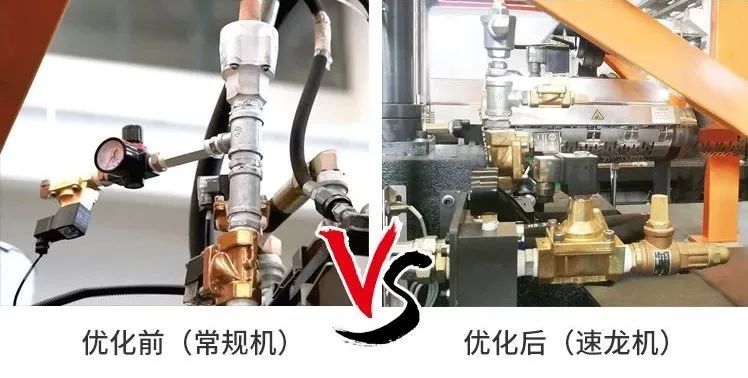

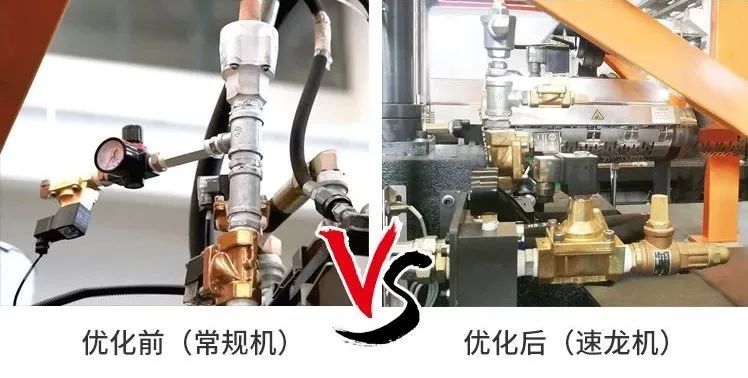

Highlight 4: Quick cooling system

The optimized Athlon machine is equipped with quick cooling system, and the air temperature of the blow pin can be maintained at 5-8 ℃; the temperature in the bottle can be quickly exchanged; and the cooling rate of the product can be increased by 2-6 seconds.

Watch the video to quickly understand the quick cooling system:

Video of the quick cooling system in the Athlon machine

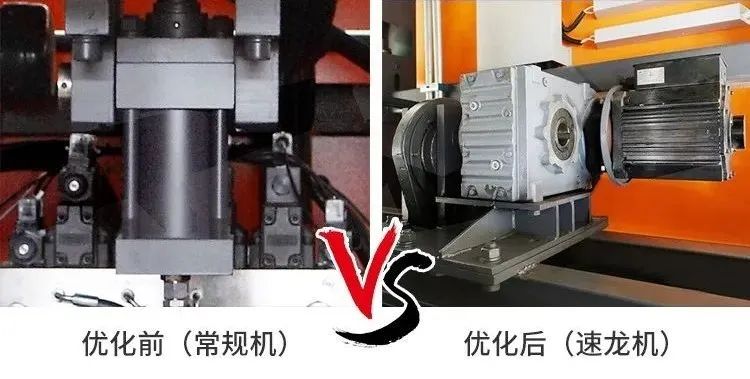

Highlight 5: Servo electric head lifting device

The optimized Athlon machine is equipped with new servo electric head lifting device. Compared with the hydraulic head lifting device of the traditional machine, it can adjust the head-up time and pause time at will, so that the customer can adjust it more conveniently.

By watching the video, you can understand the servo electric head lifting device more clearly:

Video of Athlon machine servo electric head lifting device

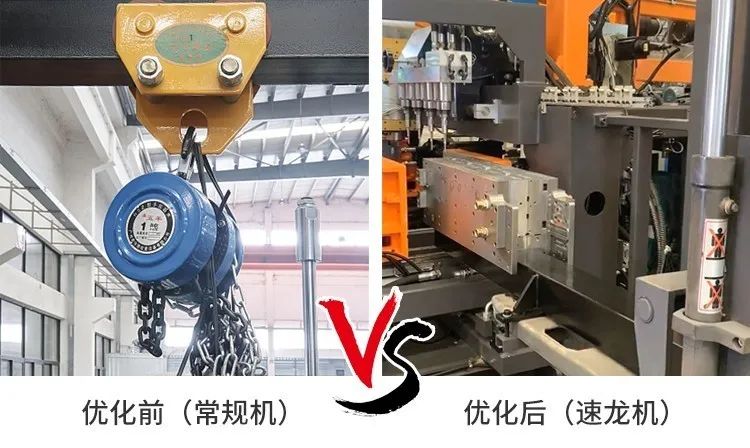

Highlight 6: Changing mold device

The Changing mold device can facilitate the loading and unloading of the mold, leaving the forklift arm space at the bottom of the machine (forklift can change the mold), making the mold changing process faster and more convenient; the front side door together with the hopper and the bottle guide rod can be safely opened; the template is loaded and positioned Compared with the hoisting mold of the traditional machine, this design is more convenient to install the mold.

Watch the video, you can clearly understand the process of mold changing:

Highlight 7: Heading tooling adjustment

After being redesigned, the Athlon machine can adjust the parison thickness of the material pipe outside the machine. The special adjustment rod is needed for adjustment. It can be adjusted outside the machine through the adjustment port, effectively protecting the safety of users.

Use the following animation to understand how to use it:

『Previous』

A Magnanimous Forceful Work,a new birth after ten years’ preparation- Leshan Athlon series come on stage with glittering appearance

『Next』 Leshan Characters Peng Zhongren: Stubborn and persistent "Boss Peng"

『Go Home』

『Next』 Leshan Characters Peng Zhongren: Stubborn and persistent "Boss Peng"

『Go Home』

Related news

Language

Language